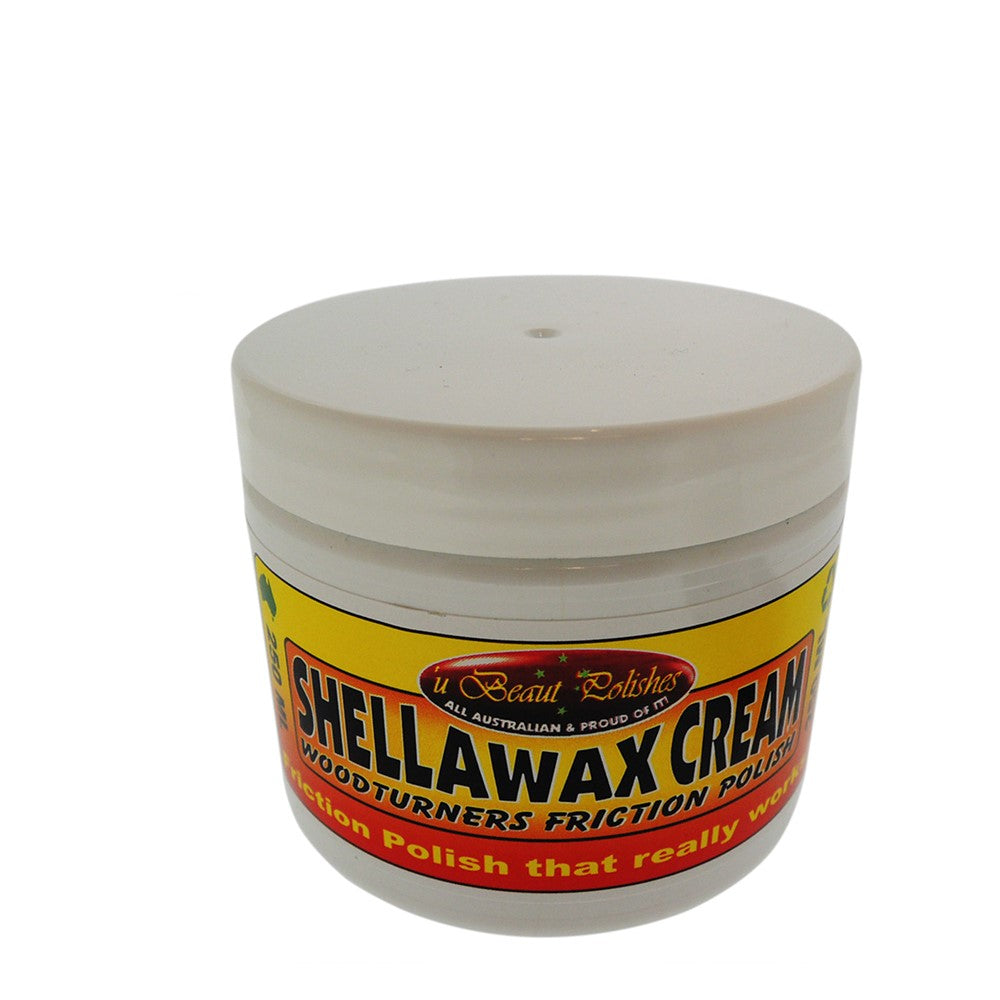

U Beaut Shellawax Cream Friction Polish 250mL

Check store availability

-

Melbourne, VICIn stock2

-

Balcatta, WAIn stock0

-

Canning Vale, WAIn stock0

Sale ends in:

U Beaut Shellawax Cream Friction Polish 250mL is backordered and will ship as soon as it is back in stock.

Request Further Information

U Beaut Shellawax Cream Friction Polish 250mL

U Beaut Shellawax Cream is a NON TOXIC one application, cream version of Shellawax woodturners friction polish from U Beaut. It the fastest and easiest to use polish of its kind on the market today. Shellawax was designed specifically for the use of woodturners. Shellawax Cream however, is designed to be used not only by woodturners, but also by woodcarvers, and for use on small flat surfaces.

On the lathe it gives a brilliant shine in seconds, can be handled immediately, is non toxic and water resistant. On woodcarvings and flat surfaces it gives a rich deep shine in a matter of minutes. Shellawax dries almost instantly when applied to spinning timber, when used on large spindles, bowls, etc. you get fine lines on the surface which look like sanding marks. These are caused by the weave of the material used to apply the polish, being set into the surface of the polish as it dries. Shellawax Cream alleviates this problem completely. So for all larger turned work Shellawax Cream is the best product to use.

Shellawax Cream is a fusion mixture of white shellac and a number of waxes including Carnauba wax & Bees wax. Contrary to popular belief neither Shellawax or Shellawax Cream contain Shellac Wax.

INSTRUCTIONS FOR USE

Before you use Shellawax Cream it is advisable to put in some fine preparation work with abrasive paper. The finer you sand the better your finish will be. Otherwise you are wasting your time and polish . For most work the best results are obtained when sanding is carried through to 1200 grit or more. At worst you should sand to at least 400 grit for a reasonable result.

Shellawax Cream is not a grain filling finish. It is not like polyurethane or other surface finishes where you can slap on a couple of coats and end up with the sanding marks filled. Quite the contrary. This is a finish that is in the timber as much as it is on the timber. It is basically unlike any other finish you have ever used before. It looks like a full blown French polish on a grand piano and brings out lights and grain in the timber that you would never have known were there.

It feels like you are touching the timber, but now the timber has an almost sensual feel to it, like it has become silk. It can add a whole new dimension to a turned item in a matter of seconds. Sounds too good to be true, but it is.

FOR WOODTURNERS

When you have finished sanding you apply Shellawax Cream as follows;

For General Application With the lathe stopped. Use a clean soft rag to quickly and evenly apply a thin coat of the Shellawax Cream to the work (the best rag to use is old flannelette sheeting or clean white T-shirt material). Turn the lathe on and with the cream moistened portion of the rag apply a steady heavy pressure to the work whilst slowly moving the rag over the entire piece. This heavy pressure is required to burn the Cream into the surface of the timber and and create the friction to make the polish shine

For small pieces (pens etc.)

The cream may be applied directly to the work with the lathe still running. Apply with a soft clean rag using a heavy pressure. Work the cream moistened portion of rag over the the entire piece until the face of the rag is dry and hard.

For Bowls & Lidded Containers etc.

Sand with abrasive grits up to 1200 or more to get a smooth line free finish on bowls and large platters etc. prior to applying the polish. Always stop the lathe before using Shellawax Cream on a bowl. Apply the cream before turning the lathe back on otherwise the cream will just be thrown off the work and you will get a patchy result.

For a High Shine. Apply as per instructions for General Application above. Satin Finish Stop the lathe, sparingly apply an even coating of the cream to the whole surface of the work rubbing it in until the rag starts to drag, allow polish to dry ( this takes 3 minutes depending on temperature). When dry turn the lathe on and buff the work with a clean soft piece of cloth (use medium to heavy pressure on the cloth turning frequently to ensure that no build up of cream remains on the work).

FOR WOODCARVERS

Sand and finish your work as you normally would. Using as fine a grit as possible. Apply a thin coating of the cream with a clean boot-brush or a soft bristled toothbrush, making sure to get into intricate designs and undercuts etc. Allow the polish to dry, (this could take from 3 to 5 minutes depending on the weather). With another clean boot-brush polish the surface as you would a pair of shoes. The highlights may also be buffed with a clean soft piece of rag. Do not apply the cream too heavily. Make sure you rub all surfaces well so as not to leave any polish in fine details, undercuts. stippling, etc.

ON FLAT SURFACES

Small surface application: Prepare the surface by sanding with abrasive paper up to 400 grit minimum. Use a clean soft rag. Dip this into the cream then put dobs of the cream on the surface of the timber approximately 2" - 3" apart (50mm - 75mm) quickly and evenly spread these dobs over the surface of the wood stop rubbing when you feel the rag start to drag. Allow the polish to dry, then buff with a clean piece of soft cloth, turning the cloth regularly.

Large surface application: When working on a large surface it is best to break the application down into a series of small sections approximately 300mm square. Apply the cream as described above to each of these small sections until the whole piece is covered. Allow to dry then buff off as for small surface application. The work is much easier if a mechanical buff is used. This can be a sheepskin, material or a circular brush, but BE WARNED you will not get a high shine if you use a high speed buff which is brand new or if you use a circular brush on high speed. The best buff for use with Shellawax, EEE Ultra Shine, Traditional Wax etc are our Swansdown Mops. Swansdown Mop A higher shine will always be achieved on a flat surface if the polish is hand buffed after buffing mechanically. You can further enhance a satin finish on flat work by applying a coat of our Traditional Wax.

PLEASE NOTE: Inductionseal must be FULLY REMOVED from jar rim before use. DO NOT REMOVE THE FOIL FROM INSIDE LID. Keep jar upright at all times, including during storage and travel. Keep the lid, rim and threads clean at all times to avoid a stuck lid. Screw lid down tight after use to stop cream from drying out. Never shake the cream jar and if dropped make sure to clean any cream from the foil in the lid, rim and thread. If needed stir cream occasionally to keep its creamy consistence. Never leave rag in jar.

Please note that this is a dangerous good and therefore can not be sent in the mail.