Bow Products

BOW Products FeatherPRO Featherboard Safety System

$46.50$54.90Unit price /UnavailableLow stock (10+ units)Milescraft

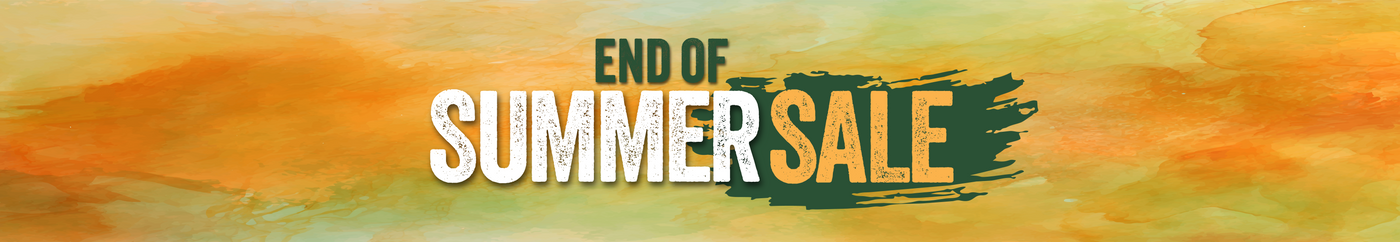

Milescraft Featherboard includes 5/8in & 3/4in Mitre Bars plus T-slot Bolts

$29.90Unit price /UnavailableIn stockBow Products

Bow Products T-Track Clamps Pack of 2 for XT XTENDER Fence

$59.90Unit price /UnavailableBow Products

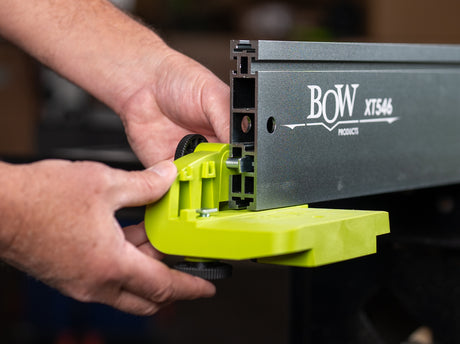

BOW Products FeatherDUO Featherboard Safety System Twin Pack Stackable

$89.00$104.90Unit price /UnavailableBow Products

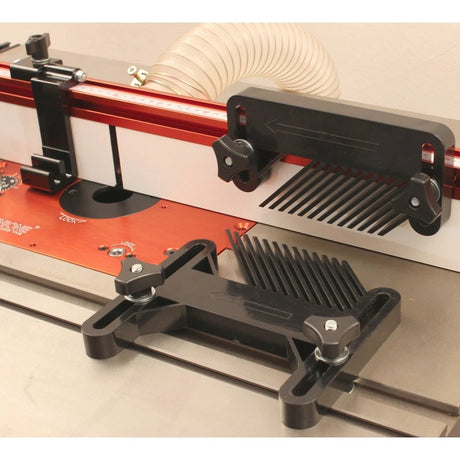

BOW Products PortaPRO Featherboard EVA Feathers Horizontal for Portable Table Saws

$39.90Unit price /UnavailableMilescraft

Milescraft D/T Featherboard Stacked includes 5/8in & 3/4in Mitre Bars plus T-slot Bolts

$59.90Unit price /UnavailableIn stockBow Products

BOW Products XT XTENDER Fence Feed Supports Pack of 2

$79.90Unit price /UnavailableIn stockBow Products

BOW Products FencePRO Featherboard EVA Feathers Stackable for Machining Safety

$64.90Unit price /UnavailableIn stockBow Products

BOW Products 46in XT XTENDER Fence Starter Set

$519.00$649.30Unit price /UnavailableBow Products

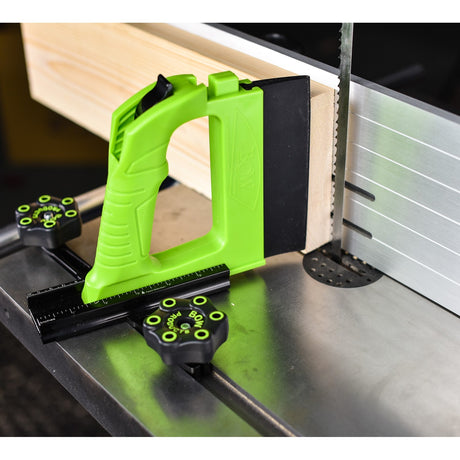

BOW Products Bandsaw GuidePRO Complete Featherboard Set

$162.00$202.70Unit price /UnavailableSherwood

Sherwood Universal Horizontal Featherboard 190mm Long 155mm Reach suits Mitre Track

$44.90Unit price /UnavailableIn stockSherwood

Sherwood Universal Vertical Featherboard 190mm Long 85mm Reach suits T-Track

$24.90Unit price /UnavailableIn stockSherwood

Sherwood Set of 4 Horizontal & Vertical Featherboards for Router Tables

$129.90$139.60Unit price /UnavailableIn stockMagswitch

Magswitch Reversible Magnetic Featherboard Starter Kit

$195.00Unit price /UnavailableIn stock

Featherboards: Precision Safety Tools for Safer, Cleaner Cuts

Featherboards are essential accessories in any woodworking setup, designed to keep workpieces securely pressed against fences or tables during cutting operations. Whether working with table saws, router tables, or band saws, featherboards dramatically reduce the risk of kickback and ensure consistently accurate cuts. Their flexible fingers apply uniform pressure without marring the surface of the wood, which is especially useful when working with delicate or expensive timber.

Modern featherboards are made from durable materials such as high-density plastic or composite polymers that resist wear while maintaining flexibility. Many models are tool-free and feature quick-release clamps, making them easy to position and adjust. They’re available in a variety of configurations—single, double-stack, or multi-directional—suiting everything from light-duty hobby work to heavy-duty production runs in professional workshops.

Using featherboards not only boosts precision but also improves user safety. By maintaining firm contact with the fence or table, they help eliminate movement that could lead to binding or loss of control. They're especially effective for long rip cuts, edge routing, and intricate shaping operations where consistency and control are critical.

For best results, featherboards should be properly aligned and adjusted according to the size and grain direction of your workpiece. It's also a good idea to use multiple featherboards in tandem for longer boards or trickier cuts. Adding these simple yet powerful tools to your woodworking routine can significantly improve both the quality of your work and your overall workshop safety.

FAQs

What is a featherboard used for in woodworking?

A featherboard is used to keep a workpiece firmly pressed against a fence or tabletop, ensuring consistent pressure and alignment while cutting. This results in cleaner, safer, and more precise cuts.

Can featherboards be used with both table saws and router tables?

Yes, featherboards are compatible with table saws, router tables, band saws, and even some jointers. They’re versatile tools designed to enhance safety and accuracy across different machines.

How do I install a featherboard?

Most featherboards can be mounted using T-slots, mitre slots, or clamps. Simply position the featherboard so that its fingers apply light pressure on the workpiece, then secure it in place before starting your cut.

Are magnetic featherboards reliable?

Magnetic featherboards are very reliable on cast-iron tables and offer tool-free setup. They provide strong holding power and quick adjustments, though they may not work on non-magnetic surfaces like aluminium.

What’s the difference between single and dual featherboards?

Single featherboards apply pressure from one side, ideal for standard operations. Dual or stacked featherboards provide additional hold and are better for taller or thicker workpieces requiring more support.

Can I make my own featherboard?

Yes, you can make a featherboard using scrap hardwood or plywood. However, commercial models offer greater durability, precision, and adjustability, often making them a better long-term solution.

Are featherboards necessary for all cuts?

While not necessary for every cut, featherboards are highly recommended for rip cuts, edge profiling, or anytime you need consistent pressure against a fence. They significantly enhance safety and cut quality.

Do featherboards work on curved cuts?

Featherboards are primarily designed for straight cuts. They are less effective for curved or freehand cuts where consistent contact with a fence or guide is not maintained.

How much pressure should a featherboard apply?

Featherboards should apply firm but flexible pressure—enough to hold the workpiece in place without impeding its movement. Too much pressure can cause drag, while too little may reduce effectiveness.