SIA Abrasives

SIA Abrasives 7979 siasponge flat Abrasive Foam Pad 115 x 140 x 5mm

$2.90Unit price /UnavailableLow stock (10+ units)SIA Abrasives

SIA Abrasives 1948 siaflex Abrasive Sheet 230 x 280mm

$1.50Unit price /UnavailableLow stock (10+ units)SIA Abrasives

SIA Abrasives 7983 siasponge flex Abrasive Foam Pad 98 x 120 x 13mm

$2.90Unit price /UnavailableIn stockSIA Abrasives

SIA Abrasives 1713 siawat Abrasive Sheet 230 x 280mm

$1.50Unit price /UnavailableIn stockSIA Abrasives

SIA Abrasives 2920 siawood Sanding Belt 100 x 610mm

$4.50Unit price /UnavailableVery low stock (9 units)SIA Abrasives

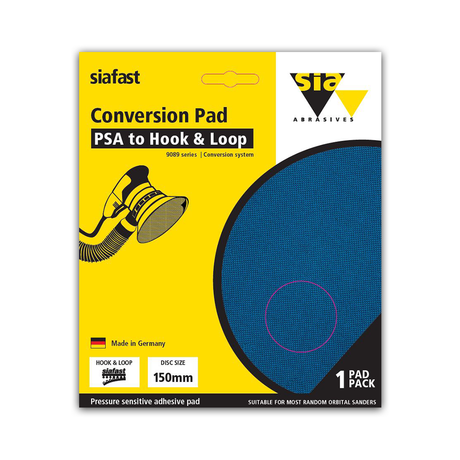

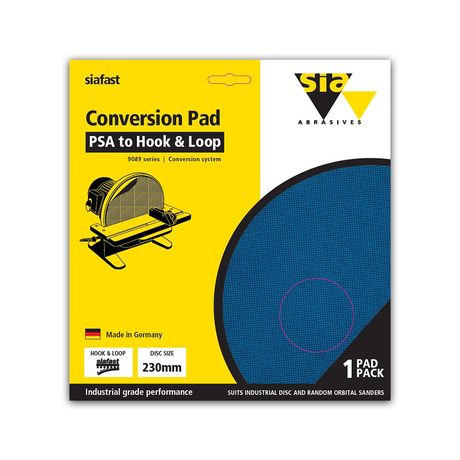

SIA Abrasives 9089 siaklett Hook & Loop Converter Pad

From $12.50Unit price /UnavailableIn stockSIA Abrasives

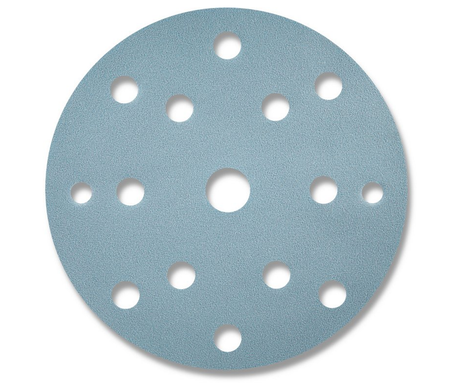

SIA Abrasives 1948 siaflex Sanding Disc 150mm 15-Hole Pack of 5

From $8.90Unit price /UnavailableIn stockSIA Abrasives

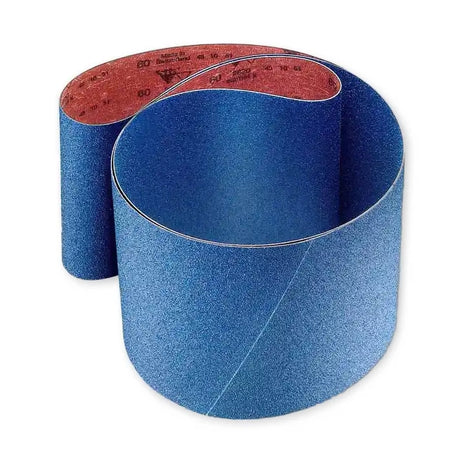

SIA Abrasives 2820 siamet Sanding Belt 150 x 1220mm Pack of 2

From $55.50Unit price /UnavailableLow stock (9 units)SIA Abrasives

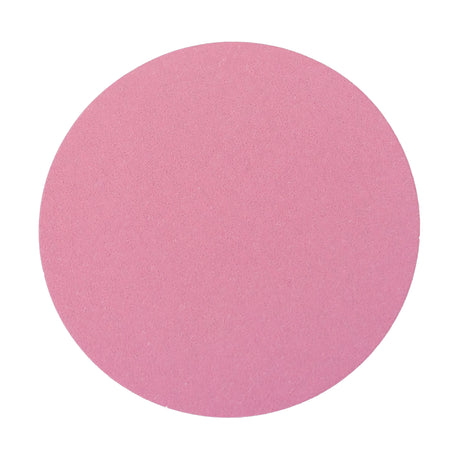

SIA Abrasives 1950 siaspeed Sanding Disc 150mm

$1.50Unit price /UnavailableIn stockSIA Abrasives

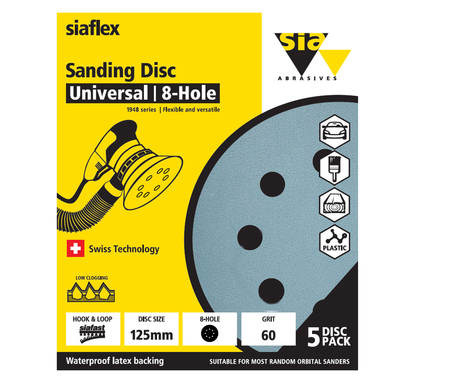

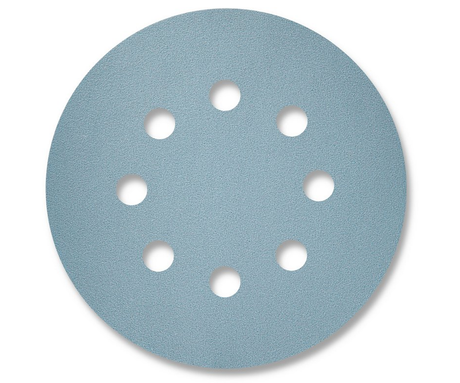

SIA Abrasives 1948 siaflex Sanding Disc 125mm 8-Hole Pack of 5

$10.50Unit price /UnavailableIn stockSIA Abrasives

SIA Abrasives 1944 siaone Sanding Disc 150mm 15-Hole Pack of 50

From $35.90Unit price /UnavailableIn stockSIA Abrasives

SIA Abrasives 1950 siaspeed Sanding Disc 125mm

$0.90Unit price /UnavailableIn stockSIA Abrasives

SIA Abrasives Cork Sanding Block 105 x 60 x 35mm

$4.50Unit price /UnavailableVery low stock (7 units)SIA Abrasives

SIA Abrasives 1815 siatop Sanding Disc 300mm

From $8.50Unit price /UnavailableIn stock

Choosing the Right Abrasives for Superior Woodworking Results

Abrasives play a crucial role in the woodworking process, from initial stock preparation to the final finishing touches. SIA Abrasives are known for their consistency, longevity, and high-performance materials, making them a preferred choice among both hobbyists and professional woodworkers. Whether sanding by hand or using a powered sander, selecting the right abrasive grit and backing type can dramatically influence the quality of your finished work.

SIA's abrasive range includes a variety of formats such as sanding sheets, discs, rolls, and belts, each designed for specific tools and applications. For example, aluminium oxide abrasives are commonly used for general-purpose sanding on wood, while ceramic and zirconia options offer greater durability and faster material removal, particularly useful on hardwoods or when shaping large surfaces.

One key advantage of premium abrasives like SIA is their anti-clogging technology, which reduces dust buildup and extends the life of the abrasive. This not only delivers a cleaner cut but also results in a more uniform surface. Investing in high-quality abrasives can reduce frustration, lower overall sanding time, and help achieve professional finishes more efficiently.

When selecting abrasives, consider the project stage—coarse grits (e.g., 40–80) are ideal for rapid material removal, while finer grits (e.g., 180–320) are better suited for final finishing or sanding between coats. Backing materials also matter; paper backings offer flexibility, while cloth backings provide added durability for heavy-duty work. Understanding these options helps in choosing the right abrasive for every woodworking task.

FAQs

What is the difference between aluminium oxide and ceramic abrasives?

Aluminium oxide is a versatile abrasive ideal for general-purpose sanding of wood and soft metals. Ceramic abrasives, on the other hand, are harder and more durable, making them suitable for aggressive sanding and long-lasting use on hardwoods and other tough materials.

How do I choose the right grit size for my project?

Use coarse grits (40–80) for heavy material removal or shaping, medium grits (100–150) for general surface preparation, and fine grits (180–320+) for finishing or sanding between coats. Start coarse and work progressively finer for the best finish.

Are SIA abrasives suitable for machine sanding?

Yes, SIA offers abrasives in formats like hook-and-loop discs, belts, and rolls that are compatible with orbital sanders, belt sanders, and drum sanders. These are engineered for consistent performance and longevity under machine use.

Why is clogging a problem with abrasives?

Clogging occurs when sanding dust and resin build up on the abrasive surface, reducing cutting efficiency and causing heat buildup. SIA abrasives often include anti-clog coatings to reduce this issue, prolonging abrasive life and improving surface finish.

Can I use the same abrasive for wood and metal?

While some abrasives are multi-purpose, it’s best to use abrasives designed for the specific material. Wood-focused abrasives typically have different bonding and grit configurations than those made for metal, which may require stronger or heat-resistant materials.

What backing material is best for heavy-duty sanding?

Cloth or fibre-backed abrasives are better suited for heavy-duty work due to their strength and tear resistance. These are ideal for belt sanders or when working with hardwoods where more pressure is applied during sanding.

How often should I change my abrasive disc or belt?

Change abrasives when you notice a decrease in cutting efficiency, visible wear, or excessive clogging that doesn’t clean easily. Regularly inspecting abrasives helps maintain consistent sanding performance and surface quality.

What is open-coat vs closed-coat abrasive?

Open-coat abrasives have gaps between abrasive grains, allowing better dust clearance and reducing clogging—ideal for woodworking. Closed-coat abrasives have a full coverage of grit, providing faster material removal but are more prone to clogging on softer woods.

Can SIA abrasives be used for finishing between coats of varnish or lacquer?

Yes, fine grit SIA abrasives (typically 220 grit and above) are ideal for smoothing surfaces between coats of finish. They help ensure better adhesion of subsequent layers and a flawless final appearance.