Torquata

Torquata Aluminium T-Track 1015mm for Jigs and Fixtures

$19.90Unit price /UnavailableIn stockTorquata

Torquata T-Track Bolts 5/16in Thread Pack of Ten

From $12.90Unit price /UnavailableIn stockTorquata

Torquata Aluminium T-Track 610mm for Jigs and Fixtures

$11.90Unit price /UnavailableIn stockTorquata

Torquata Five-Point Star Knob for 5/16in T-Track Bolts

$3.50Unit price /UnavailableIn stockTorquata

Torquata Aluminium Mitre Slider 450mm M5 & M6 Tapped

$29.90Unit price /UnavailableIn stockTorquata

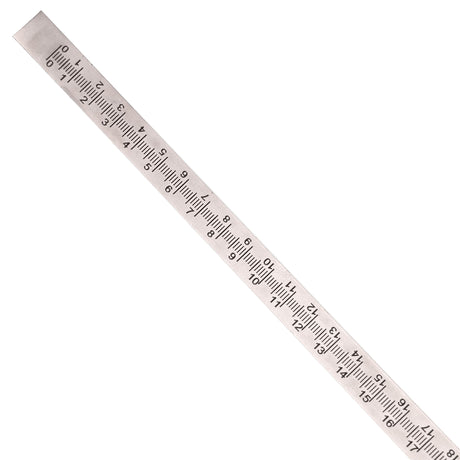

Torquata Stainless Steel Self-Adhesive Measuring Tape Metric

From $9.90Unit price /UnavailableIn stockTorquata

Torquata Large Hold-Down Clamp for T-Track Workholding

$16.90Unit price /UnavailableIn stockTorquata

Torquata Mitre Bolts for Attaching Jigs & Fixtures to 19mm 3/4in Mitre Track

$4.00Unit price /UnavailableIn stockTorquata

Torquata Aluminium Mitre Slider 650mm M5 & M6 Tapped

$39.90Unit price /UnavailableIn stockTorquata

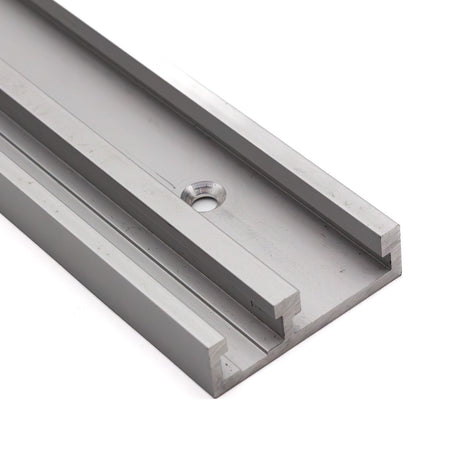

Torquata Aluminium Mitre Track for 19mm 3/4in Mitre Slot Bars

$24.90Unit price /UnavailableIn stockTorquata

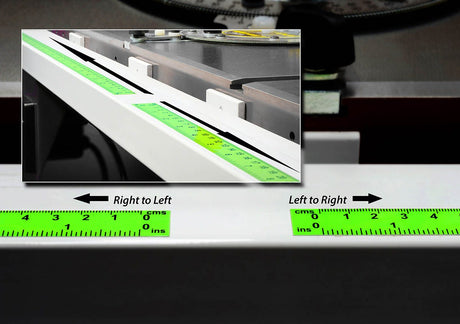

Torquata Self-Adhesive Measuring Tape Left-to-Right Metric & Imperial

$7.90Unit price /UnavailableIn stockTorquata

Torquata Four-Point Knob for 5/16in T-Track Bolts Female

$4.00Unit price /UnavailableVery low stock (10+ units)Torquata

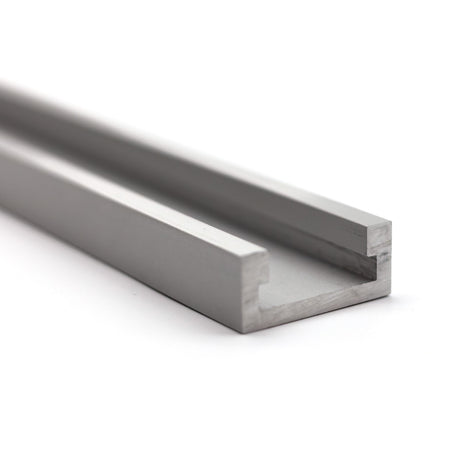

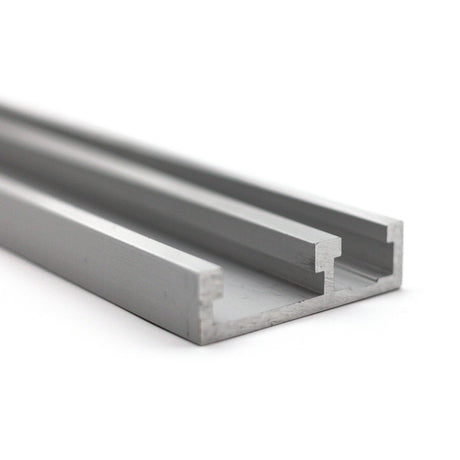

Torquata Combined Mitre & T-track Aluminium 1015mm

$29.90Unit price /UnavailableIn stockTorquata

Torquata Mitre Track Nuts 5/16in Thread Pack of Ten

$13.90Unit price /UnavailableIn stockTorquata

Torquata 118 Piece T-Track Hardware Variety Kit with Knobs & Bolts in Carry Case

$99.00Unit price /UnavailableIn stock

Upgrade Your Workshop Precision with T-Tracks and Mitre Tracks

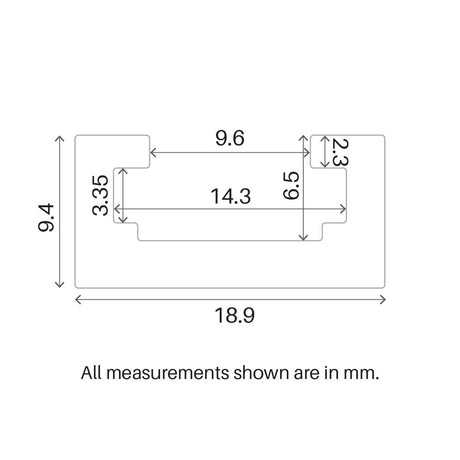

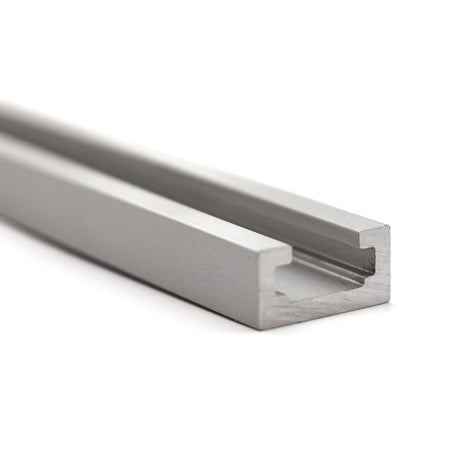

T-tracks and mitre tracks are essential components in creating highly adaptable and accurate woodworking jigs, fences, and track systems. Whether you're building a custom router table, drill press station, or crosscut sled, incorporating a reliable t-track system provides flexibility, repeatability, and precision. Made from durable extruded aluminium, these tracks offer long-lasting performance for both hobbyists and professionals.

Aluminium t track systems are compatible with a variety of accessories, including t-bolts, knobs, stops, and clamps. This makes them ideal for jig building and workholding applications. If you're comparing options like a t track at Bunnings versus specialist-grade profiles, pay close attention to slot sizing and the quality of the anodised finish. A smoother internal track allows accessories like t-slot nuts to glide effortlessly and lock down firmly.

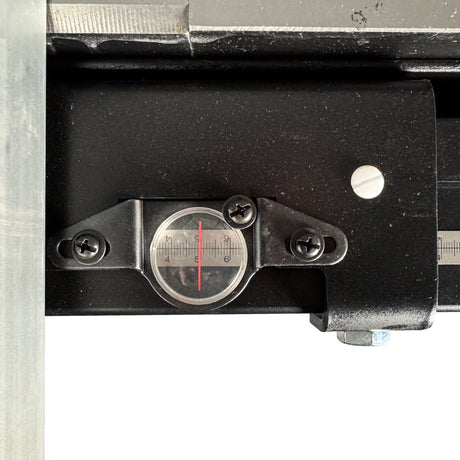

Mitre tracks, often paired with mitre gauges, are a standard feature on table saws and router tables. They allow for angled cuts and safe material guiding during complex setups. For more advanced configurations, combining a mitre track with a t-track allows for dual-axis adjustments—ideal in cabinetmaking, repeat joinery, and detailed layout work. These setups are especially effective when used in track machine designs for automated or repeat processes.

In Australia, t-tracks are becoming increasingly popular as woodworkers upgrade their benches and shop fixtures. With options like metal track profiles and modular accessories, users can create customisable workstations that enhance safety, accuracy, and efficiency. Whether you're sourcing aluminium t track Bunnings alternatives or building from scratch, these systems provide an unmatched combination of strength and versatility.

FAQs

What is a t-track used for in woodworking?

A t-track is used to mount and adjust accessories like clamps, stops, and jigs on workbenches, router tables, and drill presses. It allows for fast, secure positioning without permanently fixing components in place.

What’s the difference between a t-track and a mitre track?

T-tracks are general-purpose tracks for jig and fixture construction, while mitre tracks are typically used to guide mitre gauges or sleds on table saws and router tables for accurate angled cuts.

Are aluminium t-tracks durable?

Yes, aluminium t-tracks are highly durable, corrosion-resistant, and built to handle repetitive workshop use. They’re a preferred material for track systems due to their strength-to-weight ratio and stability.

Can I use t-slot nuts from Bunnings in these tracks?

It depends on the slot profile and size. Some t-slot nuts from Bunnings may fit standard t-track sizes, but for best performance and compatibility, it’s recommended to use matching accessories from the same supplier or verify dimensions before purchase.

What is a t-track system?

A t-track system is a modular setup using t-tracks, knobs, bolts, and accessories to allow adjustable fixtures and workholding on benches and machines. It’s commonly used for clamping, stops, and guide rails.

Can T-Tracks and Mitre Tracks be used together?

Yes, T-Tracks and Mitre Tracks can be used together to create highly versatile and functional workstations. For example, you can use a Mitre Track to guide your mitre gauge while using T-Tracks to secure clamps, stops, or other accessories in place, allowing for precise and repeatable setups.

What tools can benefit from mitre or t-tracks?

Router tables, drill presses, table saws, and band saws can all benefit from the addition of t-tracks or mitre tracks. These tracks enable better material control, safety, and setup precision across a wide range of tasks.

Can I create a track machine using t-tracks?

Yes, advanced users often integrate t-tracks into custom-built track machines for repeat routing, cutting, or drilling operations. These designs increase efficiency and ensure consistent results in high-volume workflows.

What’s the best way to mount a t-track?

T-tracks can be mounted using countersunk screws or bolts through pre-drilled holes in the track. Ensure the track is flush with the surface and secured to a stable base to avoid flex during use.

Are there accessories available for T-Tracks and Mitre Tracks?

Yes, there are numerous accessories available for T-Tracks and Mitre Tracks, including clamps, stops, knobs, hold-downs, and brackets. These accessories are designed to fit into the tracks and can be easily adjusted to suit the specific needs of your project, enhancing the versatility and functionality of your workbench or jig setup.

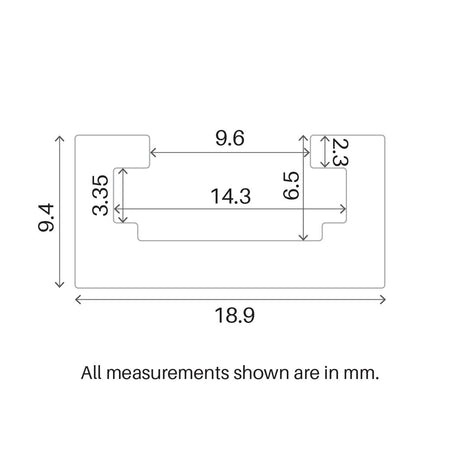

How do I choose the right size T-Track or Mitre Track for my project?

Choosing the right size T-Track or Mitre Track depends on your specific project requirements. Consider the size of the workpieces you'll be handling and the type of tools or jigs you'll be using. T-Tracks are available in various lengths and profiles, so select a track that provides enough adjustment range and support for your needs. Mitre Tracks should be chosen based on the size and compatibility of your mitre gauge or sliding tool.

Can I cut T-Tracks and Mitre Tracks to fit my workbench?

Yes, T-Tracks and Mitre Tracks can be cut to fit your specific workbench or project dimensions. Use a metal-cutting saw or hacksaw to carefully cut the track to the desired length. Ensure that the cut is clean and straight to maintain the track's functionality and to ensure smooth operation of any sliding components.