Sherwood

Sherwood Whetstone Grinder Long Knife Clamping Jig suits 12mm Support Bars

$59.90Unit price /UnavailableIn stockSherwood

Sherwood Whetstone Grinder Tool Rest 88 x 107mm suits 12mm Support Bars

$29.90Unit price /UnavailableIn stockSherwood

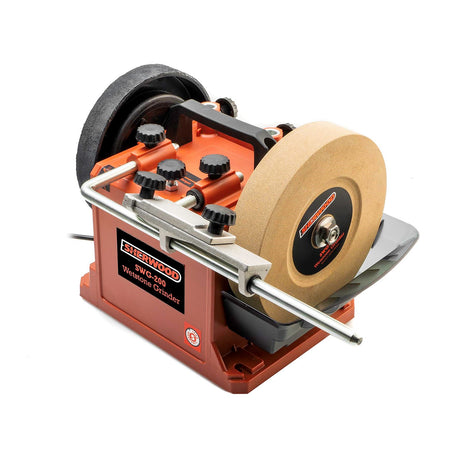

Sherwood 200mm Benchtop Wet Stone Grinder 160W Variable Speed Grinder

$399.00Unit price /UnavailableIn stockSherwood

Sherwood Whetstone Grinder Turning Gouge Jig suits 12mm Support Bars

$49.90Unit price /UnavailableIn stockTormek

Tormek Knife Angle Setter Jig for Wetstone Sharpening Grinders

$98.00Unit price /UnavailableIn stockSherwood

Sherwood Whetstone Grinder Short Knife Clamping Jig suits 12mm Support Bars

$49.90Unit price /UnavailableIn stockSherwood

Sherwood Whetstone Grinder Wheel Grader for Sharpening

$11.90Unit price /UnavailableIn stockSherwood

Sherwood Whetstone Grinder Diamond Truing Tool suits 12mm Support Bars

$69.90Unit price /UnavailableIn stockTormek

Tormek Wetstone Grinder Honing Compound for Leather Honing Wheels

$33.00Unit price /UnavailableLow stock (5 units)Sherwood

Sherwood Whetstone Grinder Angle Set-Up Jig suits 150-250mm Sharpening Wheels

$12.90Unit price /UnavailableIn stockTormek

Tormek Wetstone Grinder Standard Centering Knife Jig

$98.00Unit price /UnavailableIn stockTormek

Tormek T-8 Wet Stone Grinder 250mm 200W for Sharpening Knives and Tools

$1,645.00Unit price /UnavailableIn stockSherwood

Sherwood Whetstone Grinder Straight Edge Jig 60mm Blades suits 12mm Support Bars

$39.90Unit price /UnavailableVery low stock (2 units)Sherwood

Sherwood Benchtop Wet Stone Grinder 200mm 160W Variable Speed with Diamond Truing Tool

$439.90$468.90Unit price /UnavailableIn stockSherwood

Sherwood 250mm Benchtop Wet Stone Grinder 160W Variable Speed Grinder

$549.00Unit price /UnavailableIn stockTormek

Tormek Wetstone Grinder Stone Truing Tool

$155.00Unit price /UnavailableVery low stock (2 units)

Whetstone Grinders for Precision Sharpening and Tool Care

Whetstone grinders are purpose-built machines for achieving fine, controlled sharpening on woodworking and carving tools. Operating at slow speeds with a water-cooled grinding wheel, they prevent overheating and maintain the hardness and edge integrity of high-carbon steels. This makes them ideal for sharpening chisels, plane irons, turning gouges, knives, and other edge tools that demand precision.

Unlike dry grinders, whetstone grinders reduce the risk of bluing or temper loss by continuously cooling the blade during sharpening. This is especially important when working with thin or delicate edges where overheating can quickly cause damage. Most models feature an adjustable tool rest or jig system to maintain a consistent angle, which is critical for repeatable, razor-sharp results.

These machines are particularly well-suited to fine woodworking, where accuracy and edge quality are paramount. Many whetstone grinders also include a leather honing wheel for polishing the edge to a mirror finish. Combined with honing compound, this final step removes micro-burrs and leaves a sharper, longer-lasting cutting edge.

Whether you're a furniture maker, turner, carver, or hand tool enthusiast, a whetstone grinder offers a safe, accurate, and repeatable way to maintain your edge tools. With minimal material removal and cool grinding action, they are a smart investment for extending tool life and improving performance at the bench.

FAQs

What is a whetstone grinder used for?

Whetstone grinders are used to sharpen and hone tools like chisels, plane blades, turning tools, and knives. Their slow-speed, water-cooled grinding action ensures safe, accurate sharpening without overheating the tool.

How is a whetstone grinder different from a bench grinder?

Whetstone grinders operate at low speeds and use water for cooling, preventing heat damage and temper loss. Bench grinders run faster and are better suited for rapid material removal but carry a higher risk of overheating edges.

Do I need to use a jig with a whetstone grinder?

While not essential, using a jig helps maintain a consistent bevel angle and produces more accurate results. Most whetstone grinders support a variety of jigs for different tool types.

Can a whetstone grinder sharpen curved tools like gouges?

Yes, many whetstone grinders are compatible with jigs designed for curved or rounded edges, making them ideal for turning tools and carving gouges that require precision profiles.

What maintenance does a whetstone grinder require?

Regular maintenance includes truing the stone when it becomes uneven, keeping the water trough clean, and replacing or recharging the honing compound on the leather wheel. Always store the unit dry to prevent corrosion.

How often should I flatten or true the grinding wheel?

The wheel should be trued when it shows signs of uneven wear or becomes out of round. Most whetstone grinders include a truing tool to help maintain a flat and balanced wheel surface.

Can I use a whetstone grinder for knife sharpening?

Yes, with the appropriate jig or guide, whetstone grinders are excellent for sharpening kitchen and carving knives. The slow, controlled action ensures the blade edge remains cool and undamaged.

Is a honing wheel necessary after sharpening?

Yes, the honing wheel polishes the edge and removes any remaining burr, leaving a sharper and longer-lasting finish. It’s a vital final step for tools that require a clean, precise cut.

Are whetstone grinders suitable for beginners?

Absolutely. Whetstone grinders offer a safe and forgiving sharpening method, especially when used with jigs. They allow beginners to achieve professional results with minimal risk of damaging their tools.