Sherwood

Sherwood 200mm Benchtop Wet Stone Grinder 160W Variable Speed Grinder

$399.00Unit price /UnavailableIn stockSherwood

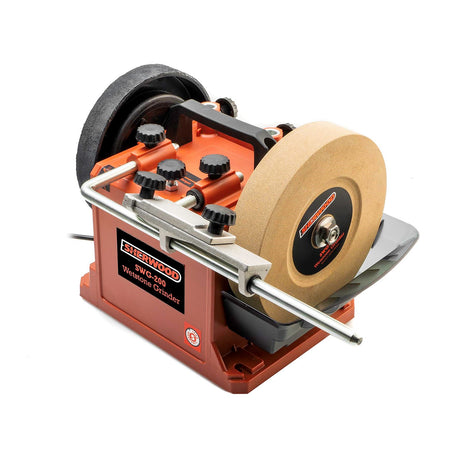

Sherwood Benchtop Wet Stone Grinder 200mm 160W Variable Speed with Diamond Truing Tool

$439.90$468.90Unit price /UnavailableIn stockTormek

Tormek T-8 Wet Stone Grinder 250mm 200W for Sharpening Knives and Tools

$1,745.00Unit price /UnavailableIn stockSherwood

Sherwood 250mm Benchtop Wet Stone Grinder 160W Variable Speed Grinder

$549.00Unit price /UnavailableIn stockSherwood

Sherwood Benchtop Wet Stone Grinder 250mm 160W Variable Speed with Diamond Truing Tool

$629.90$678.70Unit price /UnavailableIn stockTormek

Tormek T-4 Wet Stone Grinder 200mm 120W for Sharpening Knives and Tools

$995.00Unit price /UnavailableIn stockTormek

Tormek T-8 Wet Stone Grinder 250mm 200W with Free Rotating Base

$1,645.00Unit price /UnavailableIn stockTormek

Tormek T-8 Wet Stone Grinder 250mm 200W Customisable Machine for Sharpening Knives and Tools

$995.00Unit price /Unavailable

Wet Stone Sharpeners: Cool Grinding for Razor-Sharp Edges

Wet stone sharpeners use a slow-rotating, water-cooled stone that grinds blades without overheating—protecting the tool’s temper and extending its working life. Ideal for sharpening chisels, plane irons, knives, and turning tools, wet stone systems produce finely honed edges that deliver superior cutting performance in the workshop.

The cooling action of water is what sets wet stone sharpeners apart from dry grinders. It prevents the edge from burning or becoming brittle, particularly important when working with high-carbon or laminated steels. In addition to protecting the blade, wet grinding also reduces dust, improving both air quality and cleanliness in the workspace. Many systems also come with leather honing wheels to polish the edge after grinding, removing burrs and delivering a mirror finish.

These machines often support various jigs and attachments, allowing users to maintain consistent bevel angles across a wide range of edge tools. From wide plane blades to narrow carving gouges, wet stone systems accommodate many profiles with exceptional accuracy. This level of repeatability is especially useful for fine joinery, turning, and carving applications where razor-sharp edges are essential.

Whether you're a weekend woodworker or a professional tradesperson, a wet stone sharpener offers consistent, low-risk sharpening that improves tool performance and saves time in the long run. The gentle grinding action, combined with the ability to hone and polish, makes wet stone sharpening systems a staple in workshops that demand quality results with minimal guesswork.

FAQs

What tools can I sharpen with a wet stone sharpener?

You can sharpen a wide range of tools including chisels, plane irons, carving tools, turning gouges, knives, and even scissors. With the right jig, most edged tools can be sharpened accurately and safely.

How does a wet stone sharpener prevent overheating?

The grinding wheel rotates through a water bath that continuously cools both the stone and the tool. This prevents heat buildup, which can damage tool temper and edge retention.

Is a leather honing wheel necessary?

Yes, the leather wheel is used to remove any burrs left after grinding and to polish the edge to a mirror finish. This step significantly enhances sharpness and improves tool performance.

Can beginners use wet stone sharpeners effectively?

Absolutely. Wet stone systems are beginner-friendly, especially when used with guide jigs. They allow users to maintain precise angles and reduce the chance of damaging expensive tools.

How often should I true the grinding wheel?

The stone should be trued when it becomes uneven or out-of-round. Frequency depends on usage, but many systems include a truing tool to restore the wheel’s flatness and performance.

What grit levels are available on wet stone systems?

Most wet stone sharpeners use medium-coarse wheels (around 220 grit) for grinding. Additional stones or accessories may offer finer grits or Japanese water stones for high-polish finishes.

Can I use a wet stone sharpener to repair damaged edges?

Yes, wet stone grinders are excellent for reshaping or repairing chipped or worn edges. The slow grinding process allows careful removal of material without overheating the blade.

Do wet stone sharpeners work on curved edges like gouges?

Yes, with the correct jig or freehand technique, you can sharpen curved and profiled tools like turning and carving gouges. Some systems even include specific jigs for these shapes.

Is water quality important in these machines?

Clean tap water is usually sufficient. However, avoid using dirty or hard water as it may cause buildup or reduce wheel effectiveness. Always empty and dry the water trough after use to prevent corrosion.