Sherwood

Sherwood 8in Benchtop Jointer with Helical Spiral Head 1500W 2HP includes Open Stand

$1,349.00Unit price /UnavailableIn stockSherwood

Sherwood 6in Benchtop Jointer Planer Straight Cutterhead 1100W 1.5HP

$499.00Unit price /UnavailablePre-OrderSherwood

Sherwood 8in Parallelogram Jointer with Helical Spiral Head 2250W 3HP

$2,999.00Unit price /UnavailableIn stockSherwood

Sherwood 8in Wedge Bed Jointer Planer Helical Cutterhead 1500W 2HP

$2,599.00Unit price /UnavailableVery low stock (1 unit)Sherwood

Sherwood 6in Cabinet Jointer Planer Helical Cutterhead 750W 1HP

$1,749.00Unit price /UnavailableLow stock (2 units)Sherwood

Sherwood 6in Benchtop Jointer with Helical Spiral Head 1500W 2HP includes Open Stand

$1,149.00Unit price /UnavailableIn stockSherwood

Sherwood 12in Parallelogram Jointer with Helical Head 3750W 5HP

$4,799.00Unit price /UnavailableIn stockSherwood

Sherwood 6in Cabinet Jointer Planer Straight Cutterhead 750W 1HP

$899.50$1,199.00Unit price /UnavailableVery low stock (1 unit)Sherwood

Sherwood Benchtop Planer Bundle with Straight Blade Cutterhead Plus DC-50 Extractor

$1,337.00$1,407.00Unit price /UnavailableSherwood

Sherwood Deluxe Benchtop Planer Bundle with Helical Cutterhead Plus DC-50 Extractor

$2,449.00$2,577.00Unit price /UnavailableSherwood

Sherwood Pro Benchtop Planer Bundle with Helical Cutterhead Plus DC-50 Extractor

$2,925.00$3,077.00Unit price /UnavailablePre-Order

Mastering the Use of Jointers for Flawless Timber Surfacing

Jointers are foundational tools in any woodworking setup, used to create flat, straight surfaces on rough or warped timber. Their primary function is to prepare one face and one edge of a board, creating a reliable reference for further processing. By ensuring these surfaces are perfectly aligned and free of twists or bows, jointers make subsequent tasks like thicknessing, edge jointing, or panel glue-ups more precise and efficient.

Sherwood jointers are engineered with both performance and user-friendliness in mind. Common features include long cast-iron beds for better board support, spiral cutterheads for cleaner, quieter cuts, and precision fence adjustment systems to maintain square or angled edges. These design choices help reduce the risk of tear-out and ensure smooth, accurate jointing across a wide range of timber species.

When working with a jointer, it’s crucial to understand proper technique. Always begin with the concave side of a warped board down, and maintain consistent pressure over the infeed and outfeed tables as the board passes through. Adjusting the depth of cut conservatively—typically no more than 1-2mm—helps achieve better results and protects the cutterhead from stress. A sharp, well-aligned blade system is key to clean, chatter-free surfacing.

To get the most out of your jointer, pair it with a reliable dust extraction system and check the alignment of the tables and fence regularly. For jointing longer or heavier boards, consider using roller supports or working with a second person for added safety and control. With proper setup and technique, jointers become invaluable tools for producing straight, square, and true timber components for any woodworking project.

FAQs

What does a jointer do?

A jointer flattens one face of a board and squares one edge to that face. This creates a straight and square reference surface for further machining, such as thicknessing or edge gluing.

Is a jointer necessary if I have a thicknesser?

Yes. A thicknesser makes one face parallel to the opposite face, but it doesn’t flatten or straighten a warped board. A jointer is required to create that initial flat reference surface before thicknessing.

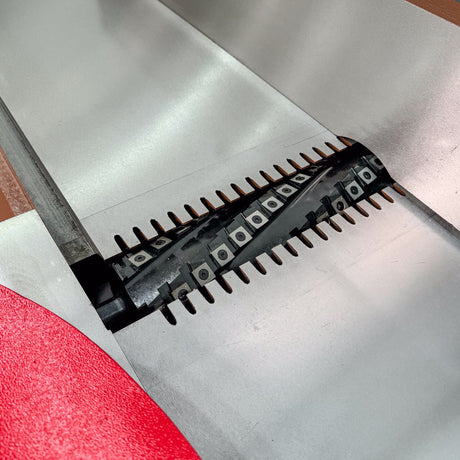

What’s the benefit of a spiral cutterhead in a jointer?

Spiral cutterheads produce smoother finishes, reduce tear-out—especially in figured or interlocked grain—and operate more quietly than traditional straight knives. They also stay sharper longer and are easier to maintain.

Can I use a jointer to square the ends of boards?

No, jointers are not designed for squaring end grain. For trimming and squaring ends, use a mitre saw, table saw with a sled, or a dedicated crosscutting tool for safer and more accurate results.

How do I know if my jointer tables are properly aligned?

You can check table alignment using a straightedge across both the infeed and outfeed tables. They should be co-planar—on the same plane. Misalignment can lead to tapered cuts or uneven faces.

What’s the maximum depth of cut I should take?

For best results, take shallow passes—typically between 0.5mm to 2mm. Deeper cuts may strain the cutterhead and lead to uneven results or tear-out, especially in hardwoods or figured grain.

Can I joint very short pieces of timber?

It’s not recommended to joint pieces shorter than about 300mm, as they may not be safely supported on the infeed and outfeed tables. Always follow safety guidelines and use push blocks for smaller workpieces.

What causes tear-out when using a jointer?

Tear-out is often caused by feeding timber against the grain or using dull blades. Switching to a spiral cutterhead or adjusting the cutting depth and feed direction can greatly reduce this issue.

Do jointers require a dust extraction system?

Yes. Jointers produce a significant amount of shavings, and proper dust extraction helps maintain visibility, reduce airborne particles, and prevent clogging or damage to the cutterhead area.