Torquata

Torquata Set of 6 Parallel Clamps 914mm Capacity Panel Clamps

$469.90$509.40Unit price /UnavailableIn stockTorquata

Torquata Set of 4 Heavy-Duty Parallel Clamps 600 & 1000mm Capacity Plus Clamp Framing Jigs

$425.00Unit price /UnavailableTorquata

Torquata Set of 4 Heavy-Duty Parallel Clamps 800mm Capacity Panel Clamps

$395.00$439.60Unit price /UnavailableTorquata

Torquata Set of 4 Heavy-Duty Parallel Clamps 1000mm Capacity Panel Clamps

$429.90$479.60Unit price /UnavailableIn stockTorquata

Torquata Set of 6 Parallel Clamps 610mm Capacity Panel Clamps

$415.90$449.40Unit price /UnavailableIn stockTorquata

Torquata Set of 4 Heavy-Duty Parallel Clamps 600mm Capacity Panel Clamps

$359.90$399.60Unit price /UnavailableVery low stock (1 unit)Torquata

Torquata Set of 4 Clamp Framing Jigs for Heavy Duty Parallel Clamps

$39.90Unit price /UnavailableIn stockTorquata

Torquata Set of 4 Heavy-Duty Parallel Clamps 1250mm Capacity Panel Clamps

$469.90$519.60Unit price /UnavailableLow stock (2 units)Bessey

Bessey Set of Four K-Body Revo Parallel Clamps 600mm Panel Clamp

$515.00$543.60Unit price /UnavailableIn stockTorquata

Torquata Set of 4 Heavy-Duty Parallel Clamps 1500mm Capacity Panel Clamps

$499.90$559.60Unit price /UnavailableIn stockTorquata

Torquata Set of 12 Parallel Clamps Plus Steel Wall Mounted Clamp Rack

$859.90$953.70Unit price /UnavailableIn stockBessey

Bessey Set of Four K-Body Revo Parallel Clamps 1000mm Panel Clamp

$699.00$703.60Unit price /UnavailableIn stockBessey

Bessey Set of Four K-Body Revo Parallel Clamps 1250mm Panel Clamp

$699.00$739.60Unit price /UnavailableIn stockBessey

Bessey Set of Four Framing Jig Blocks for K-Body Clamps

$105.90Unit price /UnavailableIn stockBessey

Bessey Set of Four K-Body Revo Parallel Clamps 800mm Panel Clamp

$569.00$599.60Unit price /UnavailableIn stockTorquata

Torquata Set of 6 Parallel Clamps 300mm Capacity Panel Clamps

$389.90$419.40Unit price /UnavailableIn stock

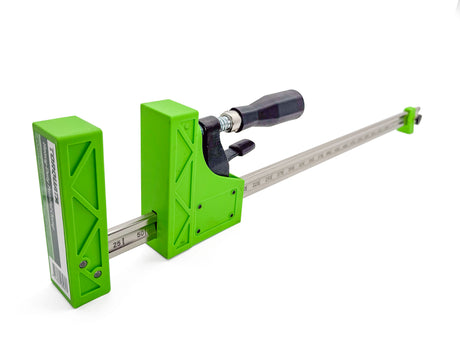

Precision Clamping for Superior Glue-Ups

Parallel clamp sets are essential tools for any woodworking enthusiast or professional seeking accurate, even pressure during glue-ups. Unlike traditional F-clamps or pipe clamps, parallel jaw clamps maintain a perfectly flat and aligned grip, preventing warping or distortion of your workpieces. This makes them especially effective for panel glue-ups, cabinet assembly, and other projects requiring precise squareness and stability.

The defining feature of these clamps is their parallel jaw design, which distributes force evenly across the clamping surface. This allows users to apply higher pressure without damaging delicate materials, making them ideal for fine joinery and veneering. Most sets include multiple sizes to accommodate a variety of project dimensions, and many offer high-quality components such as non-marring pads, quick-release mechanisms, and reinforced bars for enhanced durability.

Using clamp sets efficiently involves proper placement and even spacing. For wide panels, alternate clamps on top and bottom to distribute pressure and prevent bowing. Always perform a dry run before gluing to ensure clamp fit and access. Maintenance is simple—keep the bars and mechanisms clean of glue residue and store clamps in a way that prevents the jaws from misaligning over time.

FAQs

What are parallel clamps used for in woodworking?

Parallel clamps are primarily used for applying even pressure during glue-ups, especially for panels and cabinetry. Their jaws remain parallel under pressure, ensuring precise alignment without bowing or distortion.

How do parallel clamps differ from bar or pipe clamps?

While bar and pipe clamps provide strong clamping force, their jaws can tilt or misalign under pressure. Parallel clamps, by contrast, maintain square alignment, distributing force evenly to avoid damaging the workpiece.

Are parallel clamp sets worth the investment?

Yes, especially for precision work. Their consistent clamping pressure and square alignment greatly improve the quality of glue joints and reduce the need for rework or sanding due to misalignment.

How many parallel clamps do I need?

This depends on the size and scope of your projects. A typical starter set includes four or six clamps in various sizes. For larger glue-ups, more clamps ensure even pressure and reduce the risk of gaps or movement.

Can parallel clamps be used for non-woodworking tasks?

Yes, they can be used for tasks requiring precise pressure on flat surfaces, such as assembling composite panels or securing fixtures. However, they're designed primarily for woodworking applications.

What features should I look for in a quality parallel clamp?

Look for clamps with large clamping faces, sturdy steel bars, non-marring pads, a secure quick-release mechanism, and a high clamping force rating (usually over 1000kg for premium models).

How should I maintain and store parallel clamps?

Wipe down glue residue after each use, lubricate the screw mechanism if needed, and store them hanging or on a rack to avoid warping the bars or jaws.

Can I mix different brands of parallel clamps in a glue-up?

Yes, but be aware that pressure distribution and jaw dimensions may vary slightly. For critical projects, using matching clamps helps ensure uniform pressure and alignment.

Why do some parallel clamps have deeper throats?

A deeper throat allows the clamp to reach further into a panel or assembly, which is useful for clamping in from the edges or accessing tight spots during cabinet work.