Sherwood 13in Benchtop Pro Thicknesser with Helical Cutterhead 1800W

Check store availability

-

Melbourne, VICIn stock10+

-

Balcatta, WAIn stock5

-

Canning Vale, WAIn stock7

Sale ends in:

Sherwood 13in Benchtop Pro Thicknesser with Helical Cutterhead 1800W is backordered and will ship as soon as it is back in stock.

Request Further Information

Sherwood 13in Benchtop Pro Thicknesser with Helical Cutterhead 1800W

Built for Pro Workflows. Engineered to Perform.

Description

Description

Designed for professional workshops and serious production environments, this premium thicknesser combines heavy-duty construction, precise engineering, and superior material handling to deliver unmatched stock preparation.

The 13in Benchtop Pro Thicknesser is optimised for high-tolerance thicknessing in cabinet production, architectural millwork, musical instrument manufacturing, and engineered flooring. Compatible with automated feed tables, in-line jointer/thicknesser configurations, and CNC-prep workflows where dimensional consistency is critical. Engineered to maintain accuracy and surface quality across long work sessions, it is the ideal solution for high-volume planing of hardwoods, exotics, and composite materials.

Industrial-Grade Feed & Elevation System

The powerful 1800W motor controls a dual-speed gearbox with selectable feed rates of 4 or 7 meters per minute, allowing operators to switch between fine surface finishing and faster material removal. The gearbox is oil-lubricated and fully sealed for long-term reliability and smooth operation.

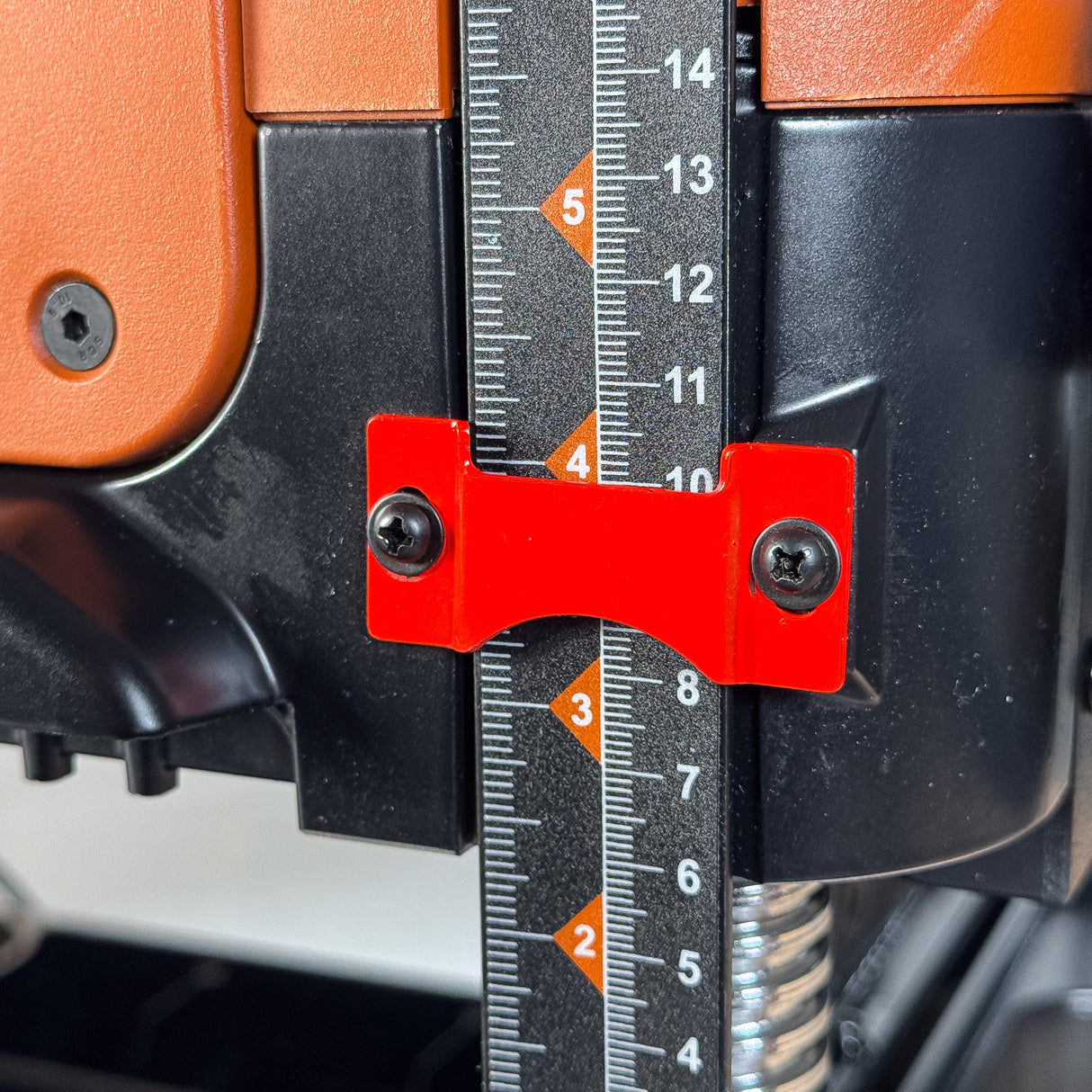

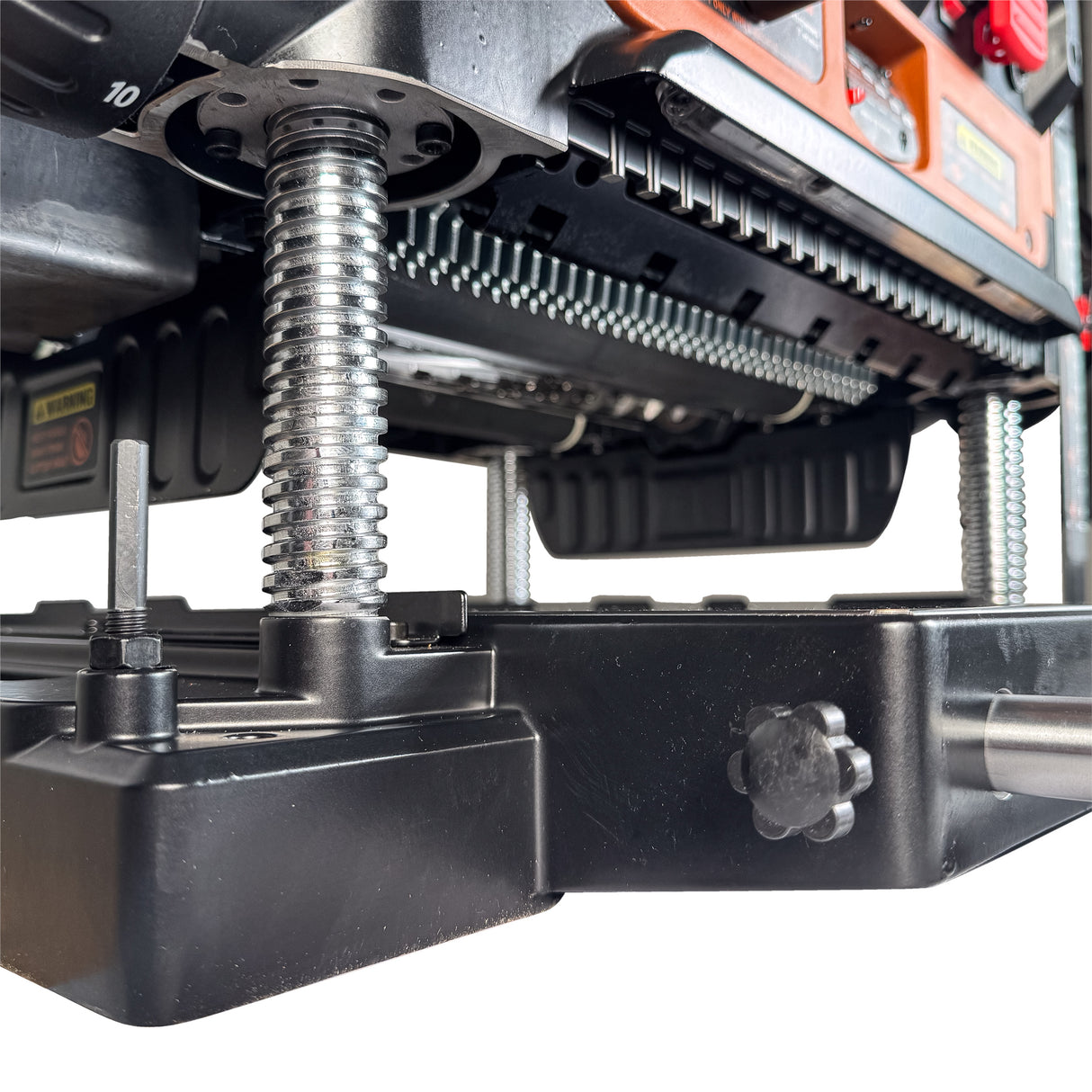

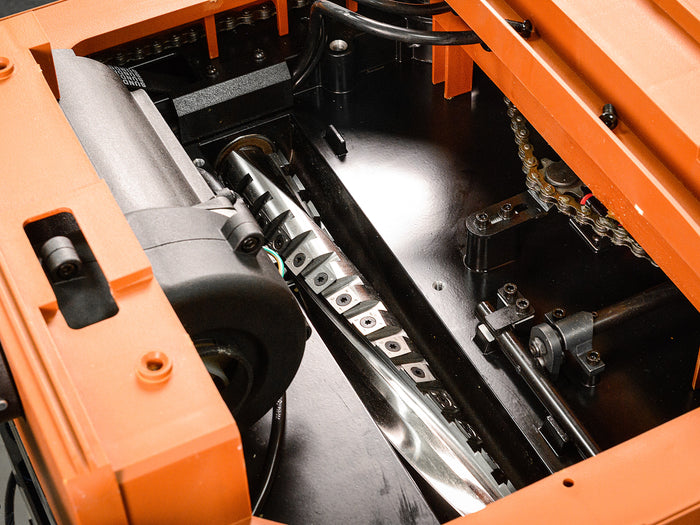

Its robust chain-and-sprocket drive system includes hardened steel gears and a multi-spline cutterhead shaft, ensuring even power delivery under load. Supporting this is a 4-post synchronized screw-lift mechanism with a 4.25:1 worm-drive reduction, maintaining precise bed parallelism during operation — a critical factor in delivering uniform thicknessing results.

High-Performance Helical Cutterhead System

At the core of the machine is a 2-row spiral helical cutterhead outfitted with thirty 4-sided solid carbide indexable inserts, positioned at a shear angle for optimised chip evacuation and minimal tear-out. These diagonally arranged indexed inserts each have a slightly radiused edge, offering a true shear cut. This configuration reduces noise levels significantly, maintains a consistently smooth surface finish even on figured or interlocked grain, and drastically reduces blade change frequency.

Carbide knives do not require sharpening. Each insert rotates individually with a Torx key to expose a fresh sharp edge. Expect to rotate the knives once for 8-10 blade changes on traditional straight HSS blades, and with four cutting edges, you can expect many years of service before replacement is required.

Premium Material Handling Components

To ensure smooth material handling, the Sherwood Pro Thicknesser features polyurethane-coated infeed and outfeed rollers that maintain consistent stock feed while protecting delicate surfaces from marring. The roller setup delivers accurate tracking even with irregular grain or dense timbers.

To minimize snipe, the machine incorporates independently tensioned, spring-loaded pressure rollers that adapt to material variation while maintaining constant downward force. Combined with fold-out, steel-reinforced infeed and outfeed tables, this setup reduces stock deflection and enhances finish quality on longer boards.

In-Built Dust Impeller

The Sherwood Pro Thicknesser is equipped with a built-in dust impeller that ensures direct chip ejection, improving cutterhead visibility and preventing clogging during extended use. It connects seamlessly to standard 4in extraction systems. An included dust collection bag can also be attached.

Features

- Quad pillar design

- Two feed speeds

- Extendable infeed and outfeed tables

- Integrated LED work light enhances visibility at the infeed point

- In-built dust impeller

- Dimension stop

- Two handles for lifting

- Includes dust collection bag

Specifications

|

Motor |

1800 W 240V 10A |

|

Max. Cutting Width |

330mm (13in) |

|

Max. Stock Thickness |

152mm (6in) |

|

Max. Width Acceptance / Depth of Cut |

W<75mm / 3.2mm W<150mm / 2.4mm W<230mm / 1.6mm W<330mm / 0.8mm |

|

Head |

Helical |

|

Inserts |

30 |

|

Feed Speed |

4 or 7 m/min |

|

Cutterhead Speed |

9400 rpm |

|

Dust Outlet |

4in or 2 1/2in |

|

Footprint |

640 x 600mm 1180 x 660mm with infeed & outfeeds extended |

|

Sound rating (at 1 metre) |

~83dB |

|

Weight |

43kg |