Torquata

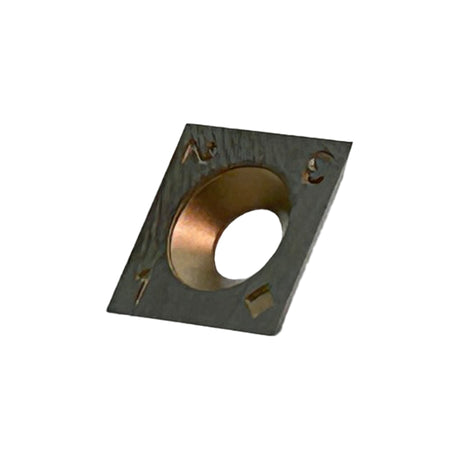

Torquata Replacement Carbide Insert Cutters suits SPRC-318-Q Router Bit

$29.90Unit price /UnavailableTorquata

Torquata 45 Degree Carbide Insert V-Groove Router Bit 1/4in Shank

$74.90Unit price /UnavailableIn stockTorquata

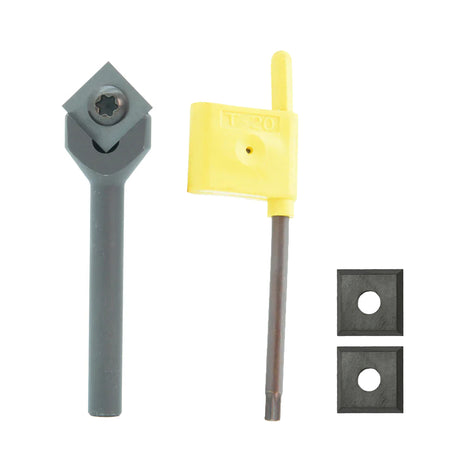

Torquata 90 Degree Carbide Insert V-Groove Router Bit & Replacement Cutters 1/4in Shank

$61.50$69.90Unit price /UnavailableIn stockTorquata

Torquata Replacement Bearings suits 1/2in Shank Carbide Insert Flush Trim Router Bit

$15.00Unit price /UnavailableIn stockTorquata

Torquata Replacement Panhead Screw M4 Thread suits Carbide Insert Router Bits

$0.06Unit price /UnavailableIn stockTorquata

Torquata 60 Degree Carbide Insert V-Groove Router Bit 1/4in Shank

$74.90Unit price /UnavailableIn stockTorquata

Torquata 60 Degree Carbide Insert V-Groove Router Bit & Replacement Cutters 1/4in Shank

$99.90Unit price /UnavailableIn stockTorquata

Torquata Replacement Carbide Insert Cutters suits VGRI-169-Q-90 Router Bit

$7.90Unit price /UnavailableIn stockTorquata

Torquata Replacement Carbide Insert Cutters suits SPRI-381-H Router Bit

$22.90Unit price /UnavailableIn stockTorquata

Torquata 90 Degree Carbide Insert V-Groove Router Bit 1/4in Shank

$64.90Unit price /UnavailableIn stockTorquata

Torquata Replacement Carbide Insert Cutters suits VGRI-186-Q-45 Router Bit

$26.90Unit price /UnavailableIn stock

Precision and Longevity with Carbide Insert Router Bits

Carbide insert router bits are a professional-grade solution for woodworkers seeking long-lasting performance and razor-sharp cutting results. Unlike traditional brazed carbide bits that require periodic sharpening, insert bits feature replaceable carbide knives that can be rotated or replaced when dull, maintaining consistent accuracy and surface finish over time. This design significantly reduces downtime and maximises the lifespan of each tool body.

These bits excel in high-volume or production settings, but they're also gaining popularity among serious hobbyists for their reliability and cost-efficiency. Because the inserts are precisely machined and indexed, there's no guesswork in alignment when replacing them—each new edge returns the tool to factory cutting specifications. The result is repeatable accuracy, reduced tear-out, and smoother finishes, especially in hardwoods and engineered materials.

Carbide insert router bits are available in a variety of profiles including straight, flush trim, rabbeting, and more specialised shapes for joinery or decorative work. They're particularly advantageous when working with abrasive materials like MDF, melamine, and plywood, which can rapidly wear down traditional carbide-tipped tools. Insert bits maintain edge retention longer and produce cleaner cuts with less resistance.

To get the most from these tools, it’s essential to match the bit to the router and application, ensure the insert screws are torqued correctly, and periodically clean resin build-up. With proper care, insert-style router bits offer an unbeatable combination of precision, durability, and convenience for demanding woodworking environments.

FAQs

What are carbide insert router bits?

Carbide insert router bits are cutting tools that use small, replaceable carbide knives instead of a permanently attached cutting edge. When the edge dulls, the insert can be rotated or replaced without needing to replace the entire bit.

What are the advantages of using insert router bits?

They offer longer tool life, consistent cutting quality, and reduced maintenance. Inserts can be replaced or rotated quickly, making them cost-effective in the long term and ideal for precision work.

Are insert router bits suitable for MDF and melamine?

Yes, these bits are particularly effective on abrasive materials like MDF and melamine. The carbide inserts hold their edge longer and produce cleaner cuts than standard router bits.

Can I sharpen carbide inserts?

Generally, no. Carbide inserts are not meant to be sharpened; instead, they are either rotated to expose a fresh edge or replaced when all edges are worn. This ensures consistent cutting quality without the need for sharpening equipment.

Do I need a special router to use insert bits?

No special router is required, but a powerful and stable router is recommended—especially when using larger-diameter bits. Always ensure the router can handle the bit's shank size and profile safely.

How do I change the inserts on a router bit?

Use the included Torx or hex wrench to remove the small screws holding the insert. Clean the seat area, rotate or replace the insert, and torque the screws evenly to ensure a secure and precise fit.

Are insert bits more expensive than traditional bits?

Initially, insert bits are more expensive, but they offer better value over time. Since only the inserts need replacing, the cost per cutting edge is lower in the long run, especially in professional or high-use settings.

Can insert router bits be used in handheld routers?

Yes, as long as the bit is properly sized and the router is powerful enough. For safety, always use appropriate speeds and secure the workpiece firmly. Larger insert bits are often better suited for table-mounted use.

What maintenance is required for insert router bits?

Keep the inserts clean and free from resin or pitch build-up. Periodically check the insert screws for tightness and ensure no debris is trapped between the insert and the tool body during changes.