Sherwood

Sherwood Heavy-Duty Polyurethane Dust Hose 4in Diameter

From $31.90$39.90Unit price /UnavailableIn stockSherwood

Sherwood Heavy-Duty Polyurethane Dust Hose 2 1/2in Diameter

From $29.90$37.90Unit price /UnavailableIn stockSherwood

Sherwood Heavy-Duty Polyurethane Dust Hose 5in Diameter

From $51.90$64.90Unit price /UnavailableIn stockSherwood

Sherwood Heavy-Duty Polyurethane Dust Hose 2in Diameter

From $29.90$37.90Unit price /UnavailableIn stockSherwood

Sherwood Heavy-Duty Polyurethane Dust Hose 1 1/2in Diameter x 3m

$27.90$34.90Unit price /UnavailableIn stockSherwood

Sherwood Wall Mount for 4in (102mm) Dust Extractor Hose Pack of 10

$26.90$30.00Unit price /UnavailableLow stock (9 units)Sherwood

Sherwood 2-1/2in Wall Spring Mount Clips for Dust Extraction Hose & Ducting

$11.90$14.90Unit price /UnavailableIn stockSherwood

Sherwood Wall Mount for 4in (102mm) Dust Extractor Hose Single Hanger

$2.50$3.00Unit price /UnavailableIn stockSherwood

Sherwood 4in Wall Spring Mount Clips for Dust Extraction Hose & Ducting

$12.90$15.90Unit price /UnavailableIn stockSherwood

Sherwood Heavy-Duty Polyurethane Dust Hose 6in Diameter

From $79.90$99.90Unit price /UnavailableIn stockShaper Tools

Shaper Tools Woven Dust Hose 2.5m for Shaper Origin Handheld CNC Router

$189.90Unit price /UnavailableIn stock

Flexible and Durable Dust Extractor Hoses for Every Workshop

Dust extractor hoses are the vital arteries of any effective dust collection system, responsible for transporting dust and debris from woodworking machinery to your extractor. These hoses need to be both flexible and strong, capable of withstanding suction pressure while navigating tight corners and connecting to a range of tool ports. The right hose ensures maximum airflow with minimal resistance, improving overall system efficiency.

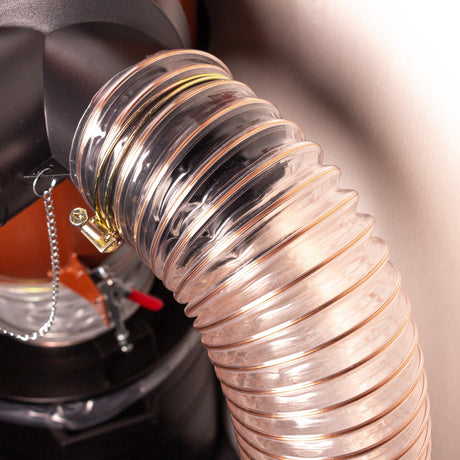

Most dust extractor hoses are made from polyurethane or PVC with embedded wire helixes to provide structural integrity and prevent collapsing under suction. Available in diameters from 32mm to 152mm and beyond, they’re compatible with everything from small handheld sanders to full-sized table saws and jointers. Clear hose options are especially popular as they allow users to visually check for blockages or clogs during operation.

Choosing the correct diameter and length is key to performance. A hose that’s too narrow can restrict airflow, while one that’s too long may cause unnecessary drag. In many cases, flexible hoses can be combined with adaptors, reducers, or blast gates to create a fully customised dust collection setup tailored to your workshop’s needs. Antistatic hose options are also available to reduce static build-up, which is crucial in high-dust environments or when collecting fine particulate matter.

To get the most from your dust extractor hose, regular inspection and cleaning is recommended. Check for kinks, tears, or signs of wear, especially near frequently flexed areas. Keeping hose runs as straight and short as possible will improve suction, while secure clamps and fittings will prevent air leaks. Whether setting up a new system or replacing a worn hose, investing in high-quality hose is a simple step that makes a big difference in dust control.

FAQs

What size dust extractor hose do I need?

The size depends on your dust extractor and the tools you're connecting. Common sizes include 63mm (2 1/2in), 102mm (4in), and 152mm (6in). Match the hose diameter to the dust port size of your tool or use adaptors for compatibility.

What material is best for dust extractor hoses?

Polyurethane and PVC are common due to their flexibility and durability. Look for hoses with steel or plastic helix reinforcement to prevent collapse. Clear hoses are helpful for spotting blockages easily.

Can I cut dust extractor hose to length?

Yes, most hoses can be cut with a utility knife or shears. Be sure to cut between the wire helix and use a smooth, clean edge to ensure a snug fit with fittings or clamps.

How do I prevent static build-up in dust hoses?

Use antistatic hoses or grounding kits. Static can build up as dust travels through plastic hose, especially with fine materials like MDF. Grounding reduces risk of shock and prevents dust from sticking inside the hose.

Can I use one hose for multiple machines?

Yes, with the help of quick-connect fittings or Y-branch connections, one hose can be moved between machines. Blast gates can also help isolate suction to a single machine at a time for better performance.

Why does my hose lose suction?

Suction loss can occur due to kinks, blockages, air leaks, or hoses that are too long or narrow. Check fittings, reduce hose length where possible, and ensure proper sealing at each connection point.

Are flexible hoses suitable for permanent installations?

While flexible hoses are great for portability and tight spaces, rigid ducting is better for permanent installations due to its smooth interior and reduced static resistance. Flexible hose is still commonly used at tool connections.

How do I connect a dust hose to my machine?

Use appropriate hose clamps or quick-connect adaptors. Most machines have dust ports that match standard hose sizes, and many universal adaptors are available for tools with non-standard sizes.

How long should my dust hose be?

Keep hose runs as short as possible to reduce friction loss and maintain suction. If a longer run is needed, use smooth, gradual bends and minimise sharp corners to optimise airflow.