Baladonia

Baladonia 1/2in Through Dovetail Template for 12in Dovetail Router Jig System

$99.00Unit price /UnavailableIn stockBaladonia

Baladonia 1/4in Box Joint Template for 12in Dovetail Jig

$59.90Unit price /UnavailableIn stockRazorsaw

Razorsaw Dozuki Japanese Saw 240mm Fine Cut Blade 24.5TPI TPE Handle

$74.90Unit price /UnavailableIn stockBaladonia

Baladonia 1/2in Box Joint Template for 12in Dovetail Jig

$59.90Unit price /UnavailableIn stockIncra

Incra ShopStop Vertical Fence Stop Bar with Micro Adjustment Metric

$95.00Unit price /UnavailableIn stockTorquata

Torquata Set of 5 Layout Saddles for Dovetails and Box Joints

$91.50$107.50Unit price /UnavailableIn stockIronbark Toolworks

Ironbark Toolworks Solid Brass Dovetail Attachments for Try Squares

$35.00Unit price /UnavailableIn stockRazorsaw

Razorsaw Dozuki Japanese Saw 240mm Rip Cut Blade 19.5TPI TPE Handle

$47.90$79.90Unit price /UnavailableIn stockIncra

Incra CleanSweep MagnaLOCK Insert Ring Set for MAST-R-Lift II Plate

$154.90Unit price /UnavailableIn stockIncra

Incra MAST-R-Lift II Router Lift & SRM-1800-N Round Body Router Motor

$1,499.00$1,628.00Unit price /UnavailablePre-OrderIncra

Incra Master Reference Guide & Template Library Set Metric

$64.90Unit price /UnavailableVery low stock (1 unit)

Dovetail Joinery Tools and Techniques

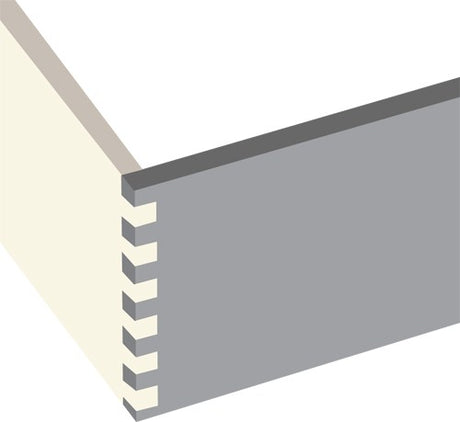

Dovetail joints are a hallmark of fine woodworking, offering both strength and beauty. These interlocking joints are commonly used in drawer construction, cabinetry, and box making, thanks to their resistance to being pulled apart. Precision is key in dovetailing, and having the right tools—such as dovetail saws, chisels, marking gauges, and dovetail jigs—makes the process significantly more accurate and efficient.

Hand-cut dovetails, though time-consuming, are a rewarding exercise in craftsmanship. They require a steady hand and attention to detail, making them ideal for traditional woodworkers who value authenticity and finesse. For those seeking quicker results, dovetail jigs and templates paired with a router provide clean and consistent joints suitable for both small-scale and production work.

When selecting tools for dovetailing, the sharpness of your chisels and the quality of your marking tools can make all the difference. Accurate layout is crucial, as even minor inaccuracies can lead to gaps or misalignment. Dovetail saws with fine teeth and thin kerfs allow for precise cuts, especially in hardwoods like jarrah or Tasmanian oak, which are common in Australian projects.

Whether you're a beginner exploring box joints or a professional cabinetmaker building heirloom furniture, mastering dovetail joinery elevates your skillset. Start with softwoods to practise your technique, and don't overlook the value of sharpening and maintaining your tools—sharp edges and clean lines are the essence of successful dovetailing.

FAQs

What is a dovetail joint used for?

Dovetail joints are primarily used in woodworking to join two pieces of timber at right angles, commonly found in drawers, cabinets, and boxes due to their strength and resistance to being pulled apart.

Do I need a dovetail jig to make dovetail joints?

A dovetail jig isn't strictly necessary but is highly recommended for consistent and accurate results, especially when using a router. For traditionalists, hand-cutting is an option but requires more skill and time.

Which tools are essential for hand-cut dovetails?

Essential tools include a dovetail saw, marking knife, square, marking gauge, chisels (ideally bevel-edged), and a mallet. High-quality sharpening stones also help maintain the cutting edges.

What angle should I use for dovetail joints?

Common dovetail angles are 1:6 for softwoods and 1:8 for hardwoods. These angles provide an optimal balance between strength and aesthetic appeal depending on the wood type.

Are dovetail joints stronger than box joints?

Yes, dovetail joints are generally stronger than box joints due to their interlocking wedge shape, which provides mechanical strength even without glue.

Can beginners make dovetail joints?

Absolutely. Beginners can start with softwood and practice hand-cutting or use dovetail jigs to simplify the process. Like any skill, practice leads to improved results over time.

How do I avoid gaps in dovetail joints?

Accurate marking and careful cutting are key. Use sharp tools, work slowly, and double-check your measurements. Paring with chisels can help fine-tune the fit before assembly.

Should I glue dovetail joints?

Yes, while dovetail joints are strong on their own, adding wood glue increases their longevity and prevents joint movement caused by wood expansion and contraction over time.

Can I use a router table for dovetail joints?

Yes, with the appropriate dovetail jig or template guide, a router table can be used effectively to produce both through and half-blind dovetails with speed and precision.